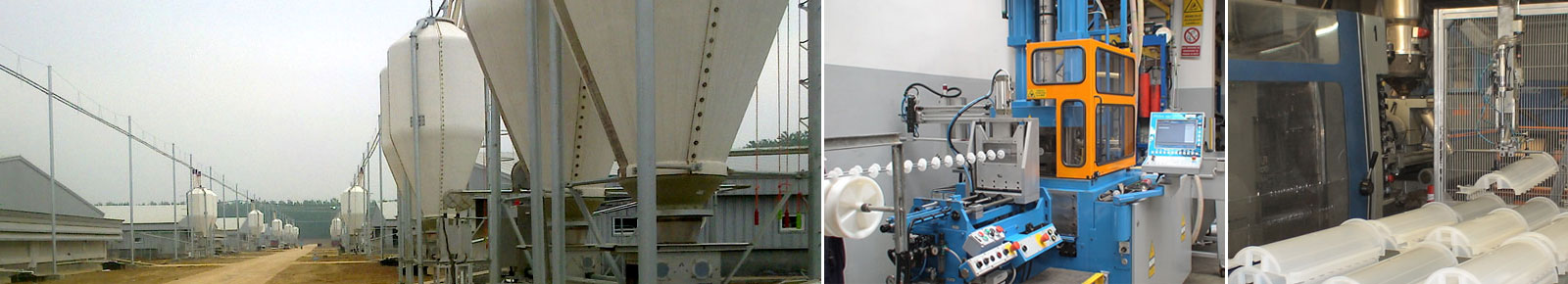

MAIN COMPONENTS OF AZA’S SYSTEMS

The drive units move the AZA cable, chain or flexible auger through the conveyor tube and are available in different versions, in stainless steel. Everything in these machines is designed and manufactured to the highest AZA standards for a long and troublefree service life.

DUPLO SERIES

The DUPLO drive units have been designed in various versions – vertical and horizontal in stainless steel finish. The very long travel of the compensating spring and the large diameter of the idle pulley wheels make the Duplo the machine of choice for long and complex circuits. Available for chain or cable conveyors for tube Ø 38, 48 and 60 mm.

D

DUPLO vertical drive unit 1 line Ø 38-48-60 mm.

D

DUPLO horizontal drive unit 1 line Ø 38-48-60 mm.

D

UNI SERIES

The UNI drive unit, available in stainless steel, has been specifically designed to handle the most demanding requirements of feed conveying both in terms of hourly capacity and system length.

The rugged and accurate construction of every component ensures not only outstanding performance but the highest degree of reliability for long troublefree operation. The UNI Drive units are available for chain or cable conveyors for tube Ø 60 mm.

D

UNI vertical drive unit 1 line Ø 60 mm.

D

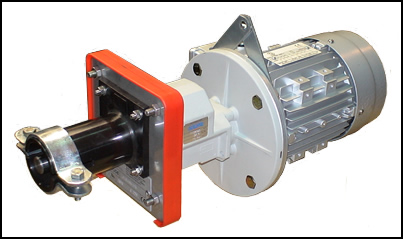

SPIRAZA SERIES

All SPIRAZA drive units for flexible augers are available in stainless steel. Two safety switches ensure that the auger stops immediately when the line is full or if it is over full. SPIRAZA drive units are available in various versions and sizes suitable for both poultry and pig feeding.

D

SPIRAZA drive unit for pig feeding or general conveyors

D

SPIRAZA drive unit for poultry feeders

D

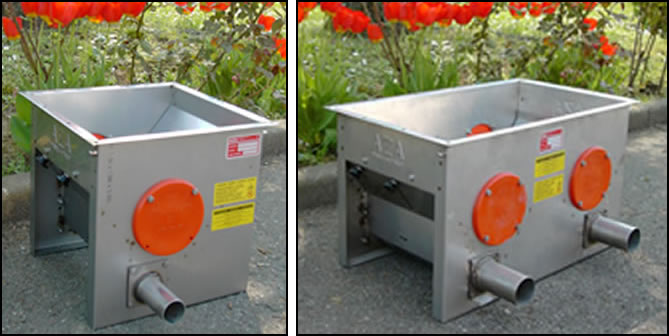

The loading hopper best demonstrates the concept of functional efficiency in feed conveying equipment.They are available for 1 and 2 feed lines in stainless steel with devices for separating foreign bodies from the feed.

CSA SERIES

The conveying cable or chain passing through the CSA hopper engages in a driving wheel which turns an auger and a cylindrical sieve. A precise amount of feed is augered onto the conveyor through the revolving sieve, avoiding any risk of overloading the system. The large inspection door and removable base allow easy acces to the hopper and fast washing operations when connected directly under the silo. CSA hoppers are made in stainless steel and are available for single or double circuits cable or chain disc conveyors in 38, 48 and 60 mm O.D. conveying tubes.

D

CSA WITH FEED RETURN SERIES

The CSA loading hopper with feed return has the same construction and operating features of the standard CSA loading hopper. It is, however, fitted with a large diameter tube to return any feed remaining in the system back into the hopper. This can be particulary useful for “Phase Feeding” when two or more different rations are been conveyed through the same system. The loading hoppers are made in stainless steel and are available for single or double circuits in 38, 48 and 60 mm. O.D. conveying tubes.

D

CSM SERIES

The CSM loading hopper is very similar to the CSA model but, in this case, the auger and sieve are motor driven. This arrangement can be particulary useful for conveying more than one ration through a single system from two or more silos. Available 38 mm, 48 mm and 60 mm conveyors in stainless steel versions.

D

UNI SERIES

UNI hoppers are designed for direct loading and feature a variable motion agitator as well as a manually operated feed flow adjuster to ensure optimum filling of the conveyor line. UNI hoppers are available in stainless steel versions for 1 or 2 feeding lines for 38 mm, 48 mm and 60 mm conveyors.

D

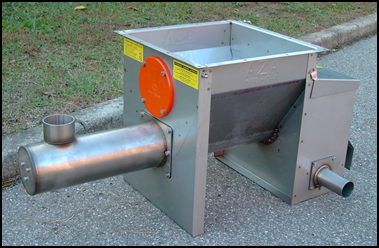

SPIRAZA S/S SERIES

The SPIRAZA stainless steel hoppers feature an adjustable spring loaded agitator plate to improve feed flow. Two large inspection doors and removable base allow easy access to the hopper and fast washing operations when connected directly under the silo. SPIRAZA stainless steel hoppers are available for the different tube sizes, for 1 or 2 lines as terminal hoppers and also in a straight-through version. Available in stainless steel.

D

SPIRAZA PLASTIC SERIES FOR EXTERNAL USE

SPIRAZA plastic loading hoppers for the outside are manufactured from stainless steel and special plastic material that render them weather-proof and resistant to hits. They are supplied with inspection door and opening bottom to simplify possible access to the inside of the hopper and washing operations when assembled below the silo. Available for tube 48, 60, 75 and 90 mm as by-pass hoppers or at the end of the line. They are the best for installations below the silo with plastic one way or two ways silo bunkers.

D

SPIRAZA PLASTIC SERIES FOR POULTRY

Plastic sturdy SPIRAZA loading hoppers for poultry systems are available for ø 48, 60, 75 and 90 mm tubes and are manufactured from stainless steel and hi-resistance plastic material. They are the best solution when used with their additional hoppers.

D

The AZA bulk bin adaptors suit the whole range of AZA hoppers. The adapters ensure that the hopers are fitted correctly to the silo and they incorporate a slide to cut off the feed flow when required. Different models can be supplied to satisfy all installation requirements. Galvanised steel, stainless steel and hi-impact plastic versions available.

D

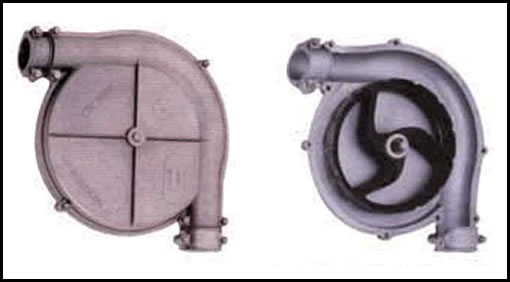

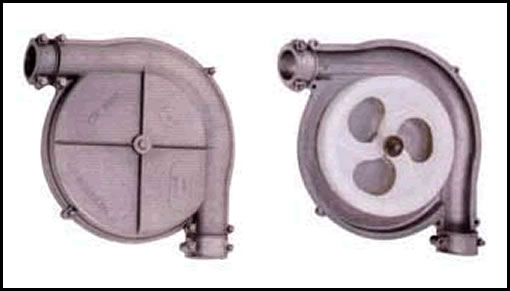

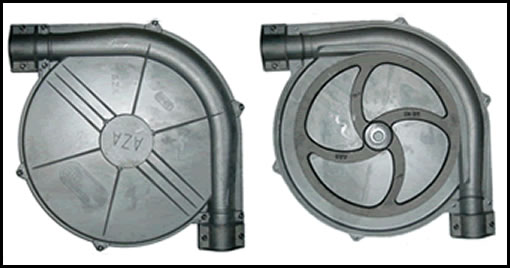

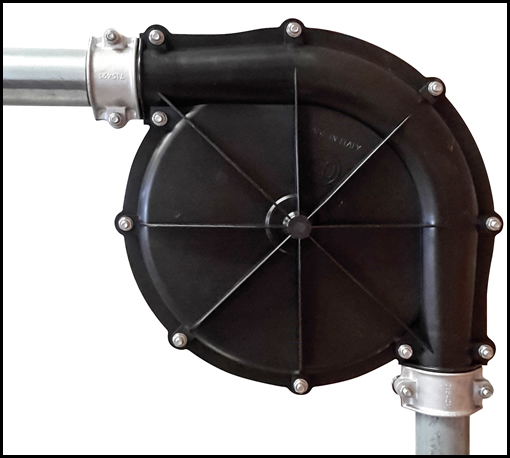

Le curve permettono la variazione di direzione del trasportatore.

The corners are available with the traditional aluminuim shells or in high resistance plastic material and with cast iron wheel or plastic wheel. Both wheels are equipped with two ball bearings. Available for conveying tubes Ø 35-38-48 mm.

Available for conveying tube Ø 60 mm. in standard version (NC) or in larger version (CT).

D

CORNER MODEL NC 38-48-60 – MADE IN ALUMINIUM WITH CAST IRON INNER WHEEL

CORNER MODEL PLT 48 – MADE IN ALUMINIUM WITH PLASTIC INNER WHEEL

CORNER MODEL CT 60 – MADE IN ALUMINIUM WITH CAST IRON INNER WHEEL

CORNER MODEL PLT 60 – COMPLETELY MADE IN HIGH RESISTANZE PLASTIC MATERIAL

Medolago (Bergamo) Italy

Phone: +39 035 901240

Fax: +39 035 902757

E-mail: info@azainternational.it

P. IVA-VAT number IT 01796080131

Cod. fiscale e N. d'iscrizione: 01940650151

Capitale sociale: € 50.000,00 i.v.